3D Design Power

3Data Expert Lite - easy 3D Printing software Download

3Data Expert Lite - The core functionality of 3Data Expert for 3D Printing and Additive Manufacturing

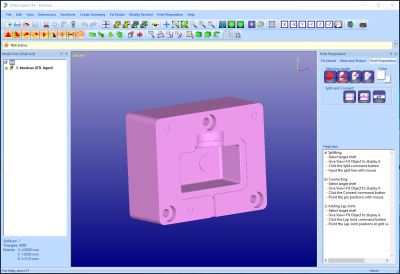

3Data Expert Lite includes the core functionality for faceted model handling for Additive Manufacturing. Repair faceted 3D models, split large sized models to fit into limited workspace and add connectors for accurate joining of the parts after the build. Also, add 3D Text tags for markups and correct part identification after the manufacturing. Slicing, slice preview and slice fixing ensure correct build with any 3D Printer. Finally, build documentation can be generated for production monitoring, PDM and quality control.

3Data Expert Lite includes the same powerful viewing, measuring and communication tools available with 3Data Expert Free. Advanced functions available with 3Data Expert Lite are described below.

3Data Expert Lite is supported on Windows XP / Vista / 7 / 8 / 8.1 / 10 / 11.

Repair faceted 3D models

3Data Expert Lite offers effective and user friendly repair tools for triangulated models. Models from different CAD systems, with or without colors, can be effectively repaired using both automatic and manual commands for Additive Manufacturing.

|

|

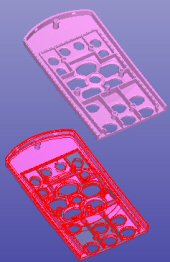

Split and connect large models

When the triangulated model is ready and repaired for AM processes, many times one problem still remains. The model may not fit into to the build area of the 3D Printing process in use. 3Data Expert Lite splitting and connection tools allow you to split and connect part halves accurately after the build.

|

|

Generate AM production reports

3Data Expert includes new commands to produce documentation for the AM print jobs. An overall Procution Screenshot can be used to identify parts on the build area and Generate Report command provides detailed information on each part in the build area.

|

|

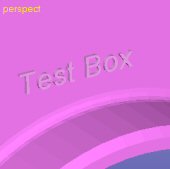

Add 3D Text, labels and new geometries

Additive Manufacturing processes allow you to build several parts at once. Adding 3D Text will help to brand a model or to tell apart the models when ready from the machine. With 3Data Expert you can add 3D Text mark-ups to recognize parts from each other. Also, primitive and freeform geometries can be generated for support or to add new features to the original part.

|

|

Slice 3D models, view and repair slices

3Data Expert includes efficient slicing routines for both part and support geometries. For accurate parts, Z Compensation can be applied to the parts before the slicing and Tool Compensation can be applied during slicing operation.

|

|

Advanced cutting functions

Medical and engineering processes may require very specific tools to cut models or to drill holes for fixtures or connectors. Cut and Hole Tools available with 3Data Expert Lite enable most delicate Boolean operations with user defined surfaces even with complex model geometries.

|

|

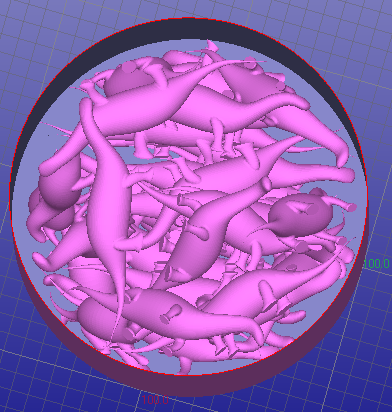

Automatic 3D nesting (optional)

3D nesting is used for positioning the parts of a model into a platform (workspace) in order to send the model to a 3D printer

|

|

3Data Expert Lite Offers:

3Data Expert Lite

- Faster display list generation and texture handling

- Improved topology generation for architectural models

- Sort Model Tree for more effective model repair and data organization

- Clean Surfaces to remove small surfaces and simplify model surface structure

- 64 bit implementation improvements to handle millions of triangles

- Production Screenshot for part identification

Communication

- Print and Email Images and 3D Geometry with Annotations and Measures

- Input STL, 3MF, VRML, ZPR, OBJ, DXF, PLY, 3DS, Collada, FBX and 3DE Files

- Write STL, 3MF, VRML, ZPR, PLY and 3DE Files

- Production Screenshots and Generate Report for build monitoring, PDM and quality control

Model Editing

- Cut, Copy and Paste 3D Data

- Multiply models for manufacturing

- Advanced Selection and Replace tools for Model Repair

- Create and Run Macros for Effective Model Repair

- Workflow and Tools Window to Access Mostly Used Repair and Manipulation commands

- Intuitive Menu Structure to Support the Workflow

- Help Text window to Aid in the Repair Process

- Different Error Filtering Levels for Repairing Models for Simulation vs. 3D Printing

3D Viewing, Transformations and Measuring

- Viewing with Colors, Textures and Clipping

- Transformations to Scale, Position, Rotate, Mirror & Platform positioning

- Change units for STL models

- Point value, Distances, Angle, Radius and Wall Thickness Measuring

New Geometry Generation

- Design of Free-Form and Primitive Surfaces

- Primitive Box, Sphere, Cone, Cylinder and Torus for Adding Features and Supports to parts

- 3D Text with for Tagging AM parts

Full Faceted Model Repair

- STL Model Verification and Automatic Repair

- Automatic Self -Intersection Removal

- Advanced Error Location for Manual Repair

- Triangle Mesh Editing with Triangle Delete, Add, Gap Bridging, Point addition and Area Triangulation

- Normal Manipulation for Shells, Surfaces and Triangles

- Model Complexity Reduction for faster visualization and memory utilization

Faceted Model Modification

- Flexible Boolean Functions and Multiple Join Functions

- Advanced Cut and Hole Tool for Cutting and Drilling

- Hole Tool for Adding User Defined Holes and Tapered Plugs 3D Printing and Additive Manufacturing Control

- Plugin command to add Direct Link to Additive Manufacturing systems

- Split models to fit on any Build area

- Connect with Pins and Lap Joint

- Platform Definition for part positioning

- Platform positioning tools

Online Help

- Extensive Online Help

- Tutorials and Advanced Model Manipulation Lessons

- Reliable Network and Standalone Licensing System